We can help you from phase 1 to manufacturing

Which phase of product development are you in?

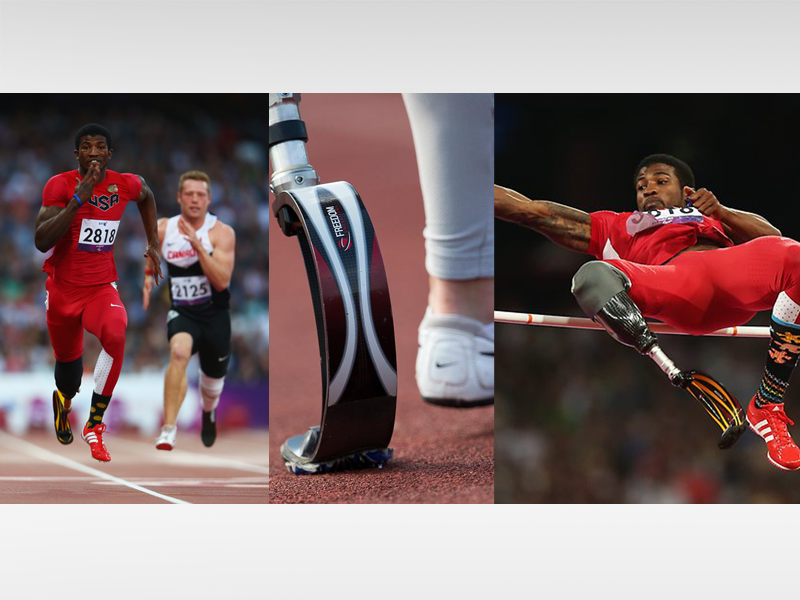

Sector Experience

Learn more:

DC has designed an end-to-end process to consistently deliver strategies, products, and experiences that streamline the user experience and your budget.

Our product development services will navigate the complexities of innovation, powered by our expert of multidisciplinary, multidimensional designers and engineers.

We Offer 4 Phases of Product Development Services

Industrial Design

PHASE 1

Our design process begins after meeting with our clients and thoroughly reviewing their objectives and design requirements. The Industrial Design team then works together to generate a series of concept sketches which feature a variety of form configurations, analyses of ergonomic usage, and preliminary engineering for component assembly. All concepts are evaluated by the client and refined based on their feedback to produce a final design direction to move forward with.

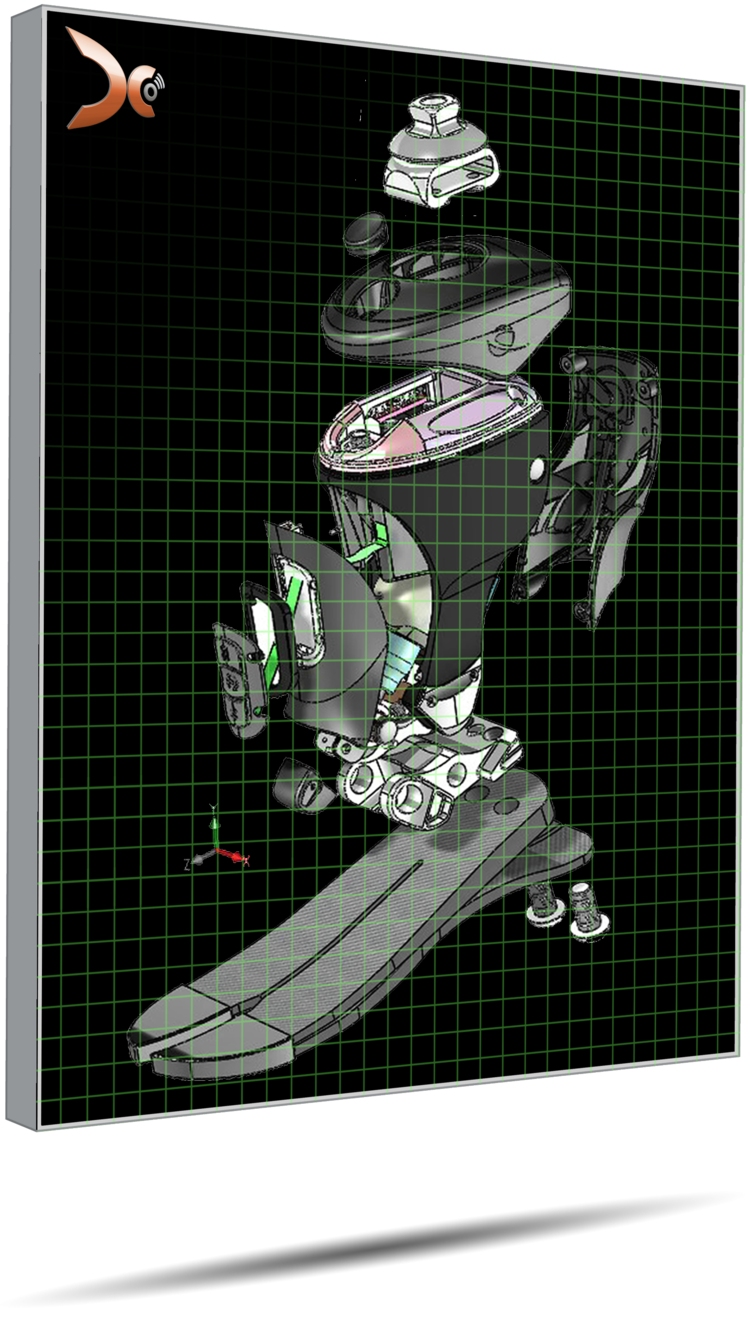

Engineering

PHASE 2

The chosen design is then handed off to the Mechanical Engineering team (as well as the Electrical and Software Engineering team if needed). They work in tandem with the Industrial Designers to develop a 3-Dimensional CAD (computer-aided design) model of the product which contains all of the functional features and tolerances necessary for prototyping, including low to high volume production and user operation, all while still maintaining the original design direction.

Prototyping

PHASE 3

Using the 3D Engineering model, various rapid prototyping processes are considered for fabrication. The prototyping process involves producing functional full scale models of the product. The prototype must be evaluated for proper fitment of components, mechanism functionality, human factors/user experience, and overall form. Engineering revisions are made based upon the findings of the prototype testing and subsequent prototypes are produced to verify issue corrections to achieve optimal functionality.

Production

PHASE 4

During our many years of product development, we have been the Original Equipment Manufacturer (OEM) for a large variety of companies. We work with our contracted manufacturing facilities both domestically and abroad to procure quality components for our in-house assembly and packaging processes. We are geared up to run both low and high volume production assembly lines right here at our facility. We also develop logos and packaging at our clients’ request for the branding and retail solutions of the products.

Frequently asked questions

Can I use you for specific product development phases?

Yes, after evaluating your products needs we can work with you specific phase development. Some of our enterprise Fortune 500 clientele tap us for engineering phases. Small-to-Mid-size clients might want to outsource the entire product development and we do all four phases.

Can you help with our patent?

Yes! We are fluent in the patent process and know exactly what it takes.

We can work with your patent attorneys and supply them the necessary documentation, product sourcing, product descriptions and renderings for a successful USPTO application.

If you are not working with a patent attorney. Design Catapult has many we have worked with for 20 years. Feel free to ask for referrals.

Do you have experience in medical regulatory and compliance?

Design Catapult has been in medical and knows the high stakes of developing for Class I/II/III medical devices and medtech. We follow better practices and can supply the necessary documentation for FDA compliance.

What software do you use?

Solidworks, Adobe, Altium, FormLabs and many more…

The Design Catapult Process: Turning Ideas Into Innovative Products

The Design Catapult Process: Turning Ideas Into Innovative Products

At Design Catapult, our approach to product development is all about turning your ideas into reality through a systematic, well-structured process. We believe that great design goes beyond aesthetics; it’s about creating functional, manufacturable products that solve real-world problems. Whether you’re a startup looking to develop your first product or an established company needing a redesign, our process ensures your product meets the highest standards of design, engineering, and usability.

Understanding Our Process

The journey from concept to market-ready product involves several stages. At Design Catapult, we guide you through every step, ensuring clear communication and a collaborative experience. Here’s an overview of our product development process:

1. Discovery and Research

Our process starts with understanding your vision, goals, and market needs. We take the time to research your industry, identify competitors, and learn about your target audience. This step is crucial to defining the problem you want to solve and ensuring that we are designing a product that meets a real demand. We also analyze trends in design, technology, and production methods to inform our design strategy.

2. Concept Development

Once we’ve gathered the insights from the discovery phase, we move to concept development. This phase includes brainstorming ideas, sketching designs, and creating initial models. We prioritize functionality, feasibility, and user experience, ensuring that every concept aligns with your vision. At this stage, we often collaborate closely with engineers to assess the practicality of the ideas, so they’re ready to be developed further.

3. Design and Engineering

In this phase, the concepts are refined and transformed into detailed designs. We integrate engineering principles such as structural integrity, ergonomics, and manufacturability into the designs to ensure that the product will function as intended in the real world. Our team combines mechanical and electrical engineering with innovative design techniques to ensure that every aspect of the product is well thought out. You can learn more about the importance of engineering in product design on Wikipedia’s Engineering page.

4. Prototyping

Prototyping is where ideas come to life. We create functional prototypes to test design concepts, user interaction, and usability. This step allows us to identify any design flaws early in the process and refine the product before full-scale production begins. Prototypes also give us valuable insights into the materials and manufacturing processes that will be used.

5. Testing and Iteration

After prototyping, we test the product for functionality, durability, and user experience. We collect feedback and make any necessary improvements. Testing is a critical part of the process, allowing us to ensure that the final product is of the highest quality. We may go through multiple iterations before the design is finalized and ready for mass production.

Why Choose Design Catapult?

Our process is designed to minimize risk and maximize success. We prioritize clear communication, collaboration, and continuous improvement to ensure that your product is developed efficiently and effectively. Whether it’s designing a consumer product, medical device, or industrial tool, we have the experience and expertise to bring your vision to life.

Get Started on Your Product Development Journey

Ready to turn your product idea into reality? The experts at Design Catapult are here to help. Visit our Contact Page to start your product development journey today. Let’s collaborate and create something amazing together.