Creating a successful product is not just about having a great idea—it’s about transforming that idea into a functional, market-ready solution. This requires a strategic, end-to-end approach that covers everything from initial design to manufacturing and production. Design Catapult is your one-stop shop for product design, manufacturing, prototyping, production planning, and product engineering. We guide you through every phase of product development, ensuring that your product is not only innovative but also feasible, cost-effective, and ready for mass production.

Creating a successful product is not just about having a great idea—it’s about transforming that idea into a functional, market-ready solution. This requires a strategic, end-to-end approach that covers everything from initial design to manufacturing and production. Design Catapult is your one-stop shop for product design, manufacturing, prototyping, production planning, and product engineering. We guide you through every phase of product development, ensuring that your product is not only innovative but also feasible, cost-effective, and ready for mass production.

In this blog, we’ll explore how Design Catapult can help bring your ideas to life through a comprehensive product development strategy. We’ll address critical areas such as the importance of product design, the role of manufacturing in scaling your product, how prototyping speeds up the development process, the necessity of production planning to ensure smooth operations, and the value of product engineering to guarantee the functionality and quality of your final product.

5 Key Questions This Blog Will Answer:

- What does the process of product design entail, and why is it so crucial to the success of a product?

- How does manufacturing help scale a product and ensure its quality?

- Why is prototyping an essential part of the product development cycle?

- How can production planning help minimize delays and reduce costs?

- What role does product engineering play in transforming your design into a functional product?

Let’s dive into each of these aspects to understand how Design Catapult can serve as your trusted partner in taking your product from concept to creation.

Product Design: The Foundation of Every Successful Product

The product design phase is where everything begins. It’s where your vision starts to take shape, and it sets the tone for how the rest of the development process unfolds. Effective product design is not just about making something look good—it’s about making something functional, user-friendly, and manufacturable. At Design Catapult, our product designers work with you to ensure that your ideas are translated into a practical, innovative, and appealing design that can eventually be produced at scale.

The Key Aspects of Product Design:

- User-Centered Design: Every product we design starts with the user in mind. We focus on creating solutions that are intuitive, functional, and solve real problems for the target audience.

- Aesthetic Appeal: While function is paramount, we understand that a product’s design must also be visually attractive to stand out in a competitive marketplace.

- Technical Feasibility: Our design team works closely with product engineers to ensure that the design is not only attractive but also feasible to produce, considering material properties, manufacturing methods, and cost constraints.

Good product design ensures that your product is viable in the real world and can be efficiently manufactured. From the very first sketch to the final 3D model, every decision is made with practicality and production in mind. A well-designed product is one that is user-centric, manufacturable, and aligned with your business goals.

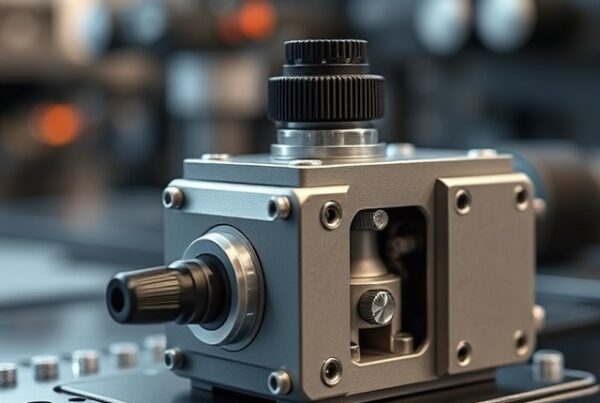

Manufacturing: Scaling Your Product with Precision and Efficiency

Once the design is finalized, the next critical step is manufacturing. Manufacturing is where your product comes to life in the form of tangible, usable units. At Design Catapult, we offer comprehensive manufacturing services that ensure your product is produced with the highest standards of quality, efficiency, and scalability.

Why Manufacturing is Crucial:

Why Manufacturing is Crucial:

- Scalability: A good manufacturing process allows you to scale your product to meet demand, whether you’re producing a small batch or mass quantities.

- Quality Control: Quality assurance is essential in manufacturing to ensure that every unit meets the required standards. We implement rigorous testing and inspection procedures to guarantee product consistency.

- Cost Efficiency: We aim to minimize production costs without compromising on quality, helping you bring your product to market at the right price point.

Our manufacturing process integrates advanced technology with skilled labor to produce high-quality products efficiently. From small-scale prototypes to full-scale production runs, we work closely with our partners to ensure that the manufacturing process is smooth and cost-effective.

Prototyping: Testing and Validating Your Ideas

Before jumping into full-scale production, it’s important to validate your ideas and designs. This is where prototyping comes in. At Design Catapult, we use prototyping as a critical tool for testing product concepts, identifying design flaws, and refining features before committing to mass production.

The Importance of Prototyping:

- Faster Iterations: Prototypes allow you to quickly test and iterate on designs, making adjustments based on feedback or unexpected results.

- Risk Reduction: By creating a prototype, we can identify potential issues early, reducing the risk of costly mistakes during production.

- User Feedback: Prototypes give you the opportunity to gather feedback from potential users, ensuring that the final product meets their needs and expectations.

With rapid prototyping, you can test your product’s form, fit, and function before investing in large-scale production. This iterative process helps ensure that the final product performs as expected and aligns with both user requirements and business goals.

Production Planning: Streamlining the Manufacturing Process

Production planning is an essential step in ensuring that your product reaches the market on time and within budget. Effective planning helps anticipate potential bottlenecks, reduce inefficiencies, and manage the complexities of manufacturing. At Design Catapult, our team works with you to map out a comprehensive production planning strategy that ensures the entire process runs smoothly.

Key Elements of Production Planning:

- Material Sourcing: We work with trusted suppliers to ensure that high-quality materials are available when needed, minimizing delays caused by supply chain issues.

- Timeline Management: We create detailed timelines for every phase of production, ensuring that deadlines are met and products are delivered on time.

- Cost Control: By identifying cost-saving opportunities early, we help you optimize production expenses and avoid unnecessary overages.

By carefully considering every aspect of production planning, we help ensure that the manufacturing process is efficient, cost-effective, and aligned with the overall product timeline.

Product Engineering: Turning Ideas into Reality

While product design lays the foundation, product engineering takes the design and makes it a functional, manufacturable reality. Product engineers work closely with the design team to ensure that the design is both feasible and efficient to produce, considering factors like materials, cost, and manufacturing techniques. At Design Catapult, our product engineers focus on making sure that your product not only looks good but also works perfectly and can be produced at scale.

How Product Engineering Enhances Your Product:

- Design Optimization: Engineers refine the design to ensure it is practical for manufacturing while maintaining functionality and aesthetic appeal.

- Material Selection: Choosing the right materials for durability, performance, and cost is critical in product engineering. We ensure that materials meet your product’s needs and budget constraints.

- Testing and Iteration: Product engineers conduct thorough testing to ensure that the product performs as expected and meets industry standards.

Through product engineering, we bridge the gap between concept and creation, ensuring that your product is not only innovative but also manufacturable and functional in the real world.

Conclusion: The Power of Design Catapult’s Comprehensive Approach

Design Catapult is your trusted partner for product design and manufacturing, offering end-to-end services that bring your ideas to life. From prototyping to production planning and product engineering, we ensure that every stage of the product development process is handled with care and expertise. Our goal is to streamline the process, reduce risk, and deliver a high-quality product that meets your business objectives.

By choosing Design Catapult as your partner, you gain access to a team of skilled professionals dedicated to your product’s success. Whether you’re working on a new product or scaling an existing one, our comprehensive services make sure your product is well-designed, manufacturable, and ready for market launch.

Key Takeaways:

- Product design is the foundation of any successful product, ensuring it is functional, attractive, and user-centered.

- Manufacturing helps scale your product, ensuring it is produced efficiently and meets quality standards.

- Prototyping reduces risk and validates ideas, helping refine your product before full-scale production.

- Production planning ensures that the manufacturing process is efficient, cost-effective, and aligned with timelines.

- Product engineering transforms design ideas into practical, manufacturable products.

Trending Metatags:

#ProductDesign #Manufacturing #Prototyping #ProductionPlanning #ProductEngineering

Social Links:

Facebook | Instagram | LinkedIn | Google Business Profile