The journey from concept to market for a medical device is complex and fraught with challenges. One of the most critical stages in this journey is medical device prototyping. It’s at this point where ideas take shape, functionality is tested, and potential issues are identified before moving into full-scale production. Whether you’re developing a brand-new medical device or improving an existing one, choosing the right prototyping partner is crucial. Design Catapult offers an all-encompassing approach to medical device prototyping, backed by years of expertise, cutting-edge technology, and a commitment to precision.

The journey from concept to market for a medical device is complex and fraught with challenges. One of the most critical stages in this journey is medical device prototyping. It’s at this point where ideas take shape, functionality is tested, and potential issues are identified before moving into full-scale production. Whether you’re developing a brand-new medical device or improving an existing one, choosing the right prototyping partner is crucial. Design Catapult offers an all-encompassing approach to medical device prototyping, backed by years of expertise, cutting-edge technology, and a commitment to precision.

In this blog, we’ll explore why Design Catapult is the right choice for your prototyping needs, focusing on how we create functional prototypes, conduct comprehensive product testing, iterate based on real-world user feedback, and make design iterations to ensure your device is ready for the market.

5 Key Questions This Blog Will Answer:

- What are the advantages of working with Design Catapult for medical device prototyping?

- How do functional prototypes contribute to the success of medical device development?

- Why is product testing critical in the prototyping phase of medical devices?

- How does gathering user feedback improve the quality of a medical device prototype?

- What role do design iterations play in the development of a successful medical device?

Let’s explore these questions in detail to understand how Design Catapult can help you bring your medical device concept to life.

Medical Device Prototyping: A Critical Step in Development

Medical device prototyping is the first concrete step toward turning an idea into a tangible product. This stage involves creating a physical or digital model of your device that demonstrates its form, function, and feasibility. Prototypes are essential because they allow you to test, refine, and optimize your design before committing to large-scale manufacturing.

At Design Catapult, we leverage advanced medical device prototyping techniques, such as 3D printing, CNC machining, and CAD modeling, to ensure that your prototype is as close to the final product as possible. Prototyping helps validate your design choices, uncover flaws, and provide insights that can only be gained through hands-on testing.

Benefits of Medical Device Prototyping:

- Early Validation: Prototypes allow you to test your ideas early, preventing costly mistakes later in the development process.

- Visualizing Functionality: Seeing and interacting with a physical prototype helps designers, engineers, and stakeholders visualize how the device will function.

- Reducing Time-to-Market: Prototyping accelerates development by identifying issues and allowing for quick fixes and iterations before moving to manufacturing.

Through medical device prototyping, we ensure that your device is not only well-designed but also functional, user-friendly, and compliant with industry standards.

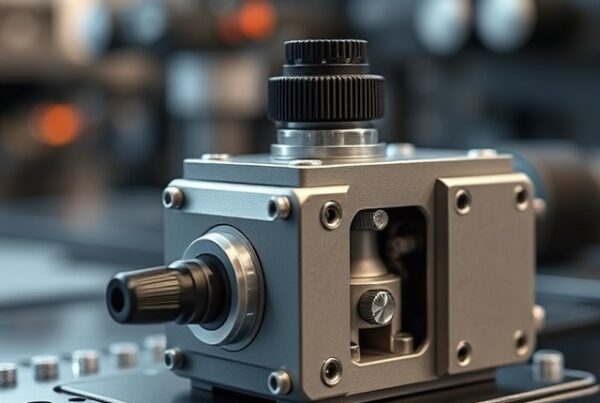

Functional Prototypes: Ensuring Your Design Works in the Real World

Creating a functional prototype is one of the most crucial steps in medical device prototyping. Unlike conceptual models that serve to illustrate a basic design, a functional prototype is a working version of your device that can be tested for performance, usability, and durability. At Design Catapult, our functional prototypes are designed to mimic the real-world conditions the device will face in clinical environments, ensuring that we identify potential issues before they arise in full-scale production.

Why Functional Prototypes Matter:

- Testing Real-World Functionality: A functional prototype allows engineers and designers to assess how the device operates in practical conditions, simulating its intended use and identifying performance gaps.

- Testing for Safety: In the medical field, safety is paramount. Functional prototypes allow you to test safety features, ensuring that the device meets regulatory standards and operates within safety parameters.

- Cost Efficiency: Testing and refining a functional prototype saves significant costs in the long run by identifying potential issues early and reducing the likelihood of costly changes during manufacturing.

At Design Catapult, we ensure that every functional prototype undergoes rigorous testing to verify its usability and reliability. This process is crucial for medical devices, where precision and dependability are non-negotiable.

Product Testing: Validating Your Prototype for Success

Product Testing: Validating Your Prototype for Success

Once a functional prototype is created, product testing becomes the next essential phase. For medical devices, product testing is vital not just for regulatory compliance, but to ensure that the device works as intended in real-world scenarios. Testing a medical device prototype provides critical insights into its performance, safety, and usability, ensuring that it meets both user needs and regulatory standards.

The Role of Product Testing in Prototyping:

- Identifying Design Flaws: Through product testing, we can uncover flaws in design that might not have been evident in the earlier stages. This includes everything from functionality to ergonomics and safety.

- Ensuring Compliance: Regulatory agencies, such as the FDA, have strict guidelines regarding the safety and efficacy of medical devices. Product testing ensures that the prototype complies with these regulations before proceeding to the next stages of development.

- Improving User Experience: Testing helps us gauge how users will interact with the device, enabling us to make necessary adjustments to enhance the user experience (UX).

Design Catapult’s approach to product testing is comprehensive and tailored to meet the unique needs of the medical device market. Whether it’s usability testing, stress testing, or safety assessments, we ensure that your prototype meets all necessary standards before moving forward.

User Feedback: Improving Your Design Through Real-World Insights

Gathering user feedback is a fundamental aspect of the prototyping process. When developing a medical device, it’s important to understand how end-users—whether they are healthcare professionals or patients—will interact with your device. User feedback helps identify areas for improvement that may not be immediately apparent through design or product testing alone.

At Design Catapult, we prioritize user feedback as a means of refining and enhancing your device. We facilitate user testing by engaging with real users early in the process to ensure that the device aligns with their needs and expectations.

The Impact of User Feedback:

- Real-World Insight: Users provide invaluable feedback based on their experience, helping us identify usability issues and design improvements that could enhance performance.

- Adapting to Needs: With direct feedback from the intended users, we can adapt the device to better fit their needs, ensuring the product has the desired impact.

- Building Confidence: When medical devices are designed with user feedback in mind, it builds trust with healthcare providers and patients, increasing adoption rates and ensuring better patient outcomes.

By incorporating user feedback into the prototyping process, we ensure that your device is practical, effective, and tailored to the people who will ultimately use it.

Design Iterations: Refining Your Prototype to Perfection

In any prototyping process, design iterations are essential. The first version of your prototype may not be perfect, but with each iteration, we refine and improve upon the design. At Design Catapult, we emphasize the importance of multiple design iterations, taking the insights gained from product testing and user feedback to make necessary improvements.

Why Design Iterations Are Vital:

- Continuous Improvement: Each iteration is an opportunity to enhance the prototype based on real data and feedback, ensuring that the final design is as functional, user-friendly, and safe as possible.

- Responding to Challenges: As challenges arise—whether related to materials, safety, or usability—design iterations allow us to make modifications to address these issues without starting from scratch.

- Optimizing for Production: Through iterative design, we ensure that the final prototype is optimized not only for functionality but also for ease of manufacturing, cost efficiency, and scalability.

Design Catapult’s commitment to continuous design iterations ensures that your prototype evolves into the most effective, efficient, and reliable medical device possible.

Conclusion: Why Design Catapult is Your Ideal Prototyping Partner

In the highly regulated and competitive medical device industry, the success of your product depends on careful planning, thorough testing, and continuous improvement. At Design Catapult, we offer comprehensive medical device prototyping services that cover every aspect of the prototyping process, from functional prototypes to product testing, user feedback, and design iterations. Our team’s expertise and commitment to excellence ensure that your device is ready for the market, compliant with regulations, and optimized for performance.

By choosing Design Catapult as your prototyping partner, you’re not just getting a service—you’re gaining a strategic ally who is invested in the success of your product.

Key Takeaways:

- Medical device prototyping is crucial for testing and validating your concept before moving to production.

- Functional prototypes provide hands-on testing and real-world insights to optimize your design.

- Product testing ensures your device meets safety, regulatory, and performance standards.

- User feedback improves the usability and effectiveness of your device, enhancing its chances for market success.

- Design iterations refine and perfect your prototype, ensuring it’s ready for mass production.

Trending Metatags:

#MedicalDevicePrototyping #FunctionalPrototypes #ProductTesting #DesignIterations #UserFeedback