Moving Forward Together in Medical Device Development: Why Choose Design Catapult?

Moving Forward Together in Medical Device Development: Why Choose Design Catapult?

Medical device development is a high-stakes endeavor, requiring precision, regulatory compliance, and a trusted partner who understands the complex needs of the healthcare industry. Whether you’re a startup entering the market or an established company looking to enhance your product portfolio, the path to success demands collaboration and expertise. At Design Catapult, we are proud members of the scientific community, dedicated to helping our clients move forward with confidence. Our team provides critical support in the development of medical devices, ensuring every step is executed with care, innovation, and a focus on quality.

This blog will explore why Design Catapult is the ideal partner for your medical device development journey, covering key considerations, the product development cycle, and how our unique approach to design, prototyping, and quality management sets us apart.

Key Questions We’ll Answer:

- What makes Design Catapult a leader in medical device development?

- How does Design Catapult’s product development process ensure top-quality results?

- Why is quality management vital in medical device development, and how do we excel at it?

- What does the design process at Design Catapult look like, and how does it meet industry standards?

- How does prototyping contribute to the success of medical devices, and what role do we play in this stage?

The Importance of Medical Device Development: Why Design Catapult?

The development of medical devices is a multifaceted process, requiring rigorous testing, design, and manufacturing to meet strict regulatory requirements. For medical devices to be both safe and effective, a dependable partner is essential to navigate these complexities.

Design Catapult stands out as a leader in medical device development, offering:

- Regulatory Expertise: With a deep understanding of FDA regulations, ISO standards, and global compliance, we help guide your product through the approval process with confidence.

- Tailored Solutions: From concept to market, we align with your vision and needs, providing customized solutions to meet your specific goals.

- End-to-End Support: Our team handles all phases of development—from initial design through production—minimizing risks and accelerating your product’s time to market.

Proven Track Record: With experience working alongside renowned medical companies like Johnson & Johnson, we have a history of delivering successful, high-quality results.

The Product Development Process: Ensuring Success

At Design Catapult, we employ a comprehensive, step-by-step approach to medical device product development, ensuring meticulous design, engineering, and testing.

Key Stages in Our Product Development Process:

- Initial Consultation & Ideation: We begin by thoroughly understanding your needs, conducting market research, feasibility studies, and user experience evaluations to guide the concept phase.

- Design & Engineering: Once the direction is set, our team utilizes cutting-edge CAD software and engineering tools to develop detailed models, assess feasibility, and refine designs.

- Prototyping & Testing: Prototypes are created to validate design concepts, allowing us to test functionality and gather feedback. Testing includes:

- Fitment, functional, and human factors testing

- Compliance & Manufacturing: As development nears completion, we ensure the design complies with all regulatory standards and manage material procurement and manufacturing coordination.

This structured approach ensures that your medical device is not only innovative but functional, safe, and ready for market success.

Quality Management: A Pillar of Medical Device Development

Quality Management: A Pillar of Medical Device Development

In the highly regulated world of medical devices, quality management is paramount. Any deviation from industry standards can cause costly delays and jeopardize safety.

At Design Catapult, we prioritize quality management throughout the development cycle, focusing on:

- Regulatory Compliance: From FDA 21 CFR Part 820 to ISO 13485, we ensure adherence to all relevant standards.

- Documented Processes: Every step of our development process is documented for traceability and accountability.

- Continuous Improvement: We integrate client feedback and testing results to refine processes and designs for optimal performance.

- Risk Management: Regular risk assessments ensure potential issues are identified and addressed before product launch.

By maintaining rigorous quality control, we guarantee that your product will meet all regulatory and safety standards.

The Design Process: A Collaborative Approach

A successful medical device starts with a strong design process. At Design Catapult, our approach incorporates:

- User-Centered Design: We focus on the end-user—healthcare professionals and patients—ensuring that the device is intuitive, safe, and effective.

- Iterative Design: Our iterative approach involves refining the product based on testing and feedback to achieve optimal performance.

- Cross-Disciplinary Collaboration: Engineers, designers, and regulatory experts work closely together to ensure the product is well-rounded and market-ready.

- Prototyping & Refinement: Multiple prototypes are tested and refined to perfect the design and functionality.

This holistic approach ensures your device is not only functional but also compliant and optimized for the marketplace.

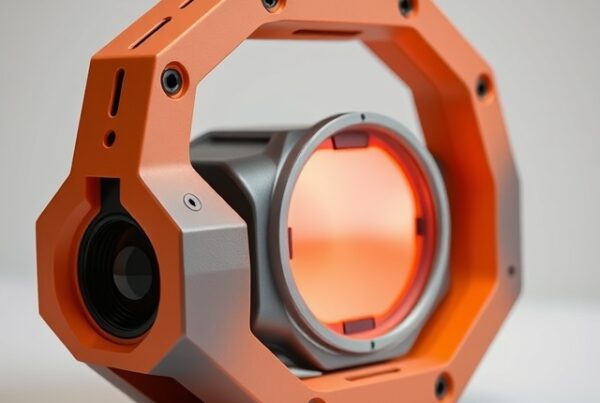

Prototyping: Connecting Design to Production

Prototyping is a crucial bridge between design and production, enabling early-stage testing and validation. At Design Catapult, our advanced prototyping capabilities ensure your device is ready for the next stage with the highest confidence.

Benefits of Prototyping in Medical Device Development:

- Functionality Testing: Early prototypes allow us to test if the device works as intended, identifying any design flaws early.

- User Experience Testing: Prototypes allow us to test how the device interacts with healthcare professionals and patients, ensuring usability.

- Regulatory Readiness: Prototypes help address regulatory concerns before final approval.

- Cost-Effective Iterations: By testing prototypes early, we minimize expensive changes later in the process.

- Accelerated Time to Market: Prototyping helps us identify and solve design challenges quickly, streamlining the development timeline.

Through prototyping, we ensure that your medical device is fully validated and ready for production.

Conclusion: Design Catapult—Your Trusted Partner in Medical Device Development

At Design Catapult, we provide comprehensive, expert-driven medical device development solutions. From concept ideation to prototyping and final production, we ensure that your device meets all regulatory requirements, performs safely, and arrives at market on time. Our unique combination of quality management, industry-leading design processes, and advanced prototyping makes us the ideal partner for your next project.

As members of the scientific community, we are committed to moving healthcare innovation forward, one successful medical device at a time.

Key Takeaways:

- Regulatory Expertise: We ensure full compliance with FDA, ISO, and other industry regulations.

- Comprehensive Development: We manage every phase from design to manufacturing for a seamless process.

- User-Centered Design: Our designs focus on usability and functionality, ensuring optimal outcomes for healthcare providers and patients.

- Advanced Prototyping: Prototyping is key to validating functionality and ensuring regulatory compliance.

- Rigorous Quality Management: We adhere to the highest standards of quality to deliver reliable, safe medical devices.

Partner with Design Catapult to turn your medical device concept into a high-quality, market-ready product that makes a meaningful impact on the healthcare industry.

Trending Metatags

#medicaldevicedesign, #productdevelopment, #engineering, #qualitymanagement, #prototyping, #healthcareinnovation

Social Media

Follow us on:

Facebook | Instagram | LinkedIn | Google Business