Innovation thrives on taking ideas from the realm of imagination and turning them into tangible realities. Prototyping plays a crucial role in this process, acting as a bridge between the initial spark of an idea and the final, polished product. Whether you’re revolutionizing a household appliance or transforming the airline industry, prototyping allows you to test, refine, and ultimately validate your design before it goes into full production.

Imagine this: You have a vision for a revolutionary airplane cart system that empowers passengers to easily access drinks and snacks during their flight. This innovative system eliminates the need for traditional stewardess service, offering convenience and increased efficiency. But how do you translate this exciting concept into a functional reality?

This is where the power of prototyping comes in.

Test and Refine Before Production: Prototyping Allows You to Visualize and Test Your Product’s Functionality

Prototyping allows you to create a physical representation of your design, enabling you to:

- Visualize your concept: Having a prototype in hand allows you to see your design come to life outside the confines of a computer screen. This tangible representation provides valuable insight into the product’s size, usability, and overall user experience.

- Test functionality: Prototypes are essential for testing the functionality of your design. You can physically interact with the prototype, simulate real-world usage scenarios, and identify any potential issues with maneuverability, product access, or user interaction.

- Gather feedback: Prototypes are invaluable tools for gathering feedback from potential users. Share your prototype with colleagues, industry experts, or even potential customers to gain valuable insights into how the product can be improved.

By creating and iterating on prototypes, you can refine your design to ensure it not only looks great but also functions flawlessly. This iterative process minimizes the risk of costly mistakes during full-scale production.

DesignCatapult: Your Partner in Prototyping Success

At Design Catapult, we understand the power of prototyping and offer a comprehensive range of rapid prototyping services to bring your vision to life. Our team of experienced engineers and designers will collaborate with you to select the most suitable prototyping method for your project.

Here are some of the prototyping methods we offer:

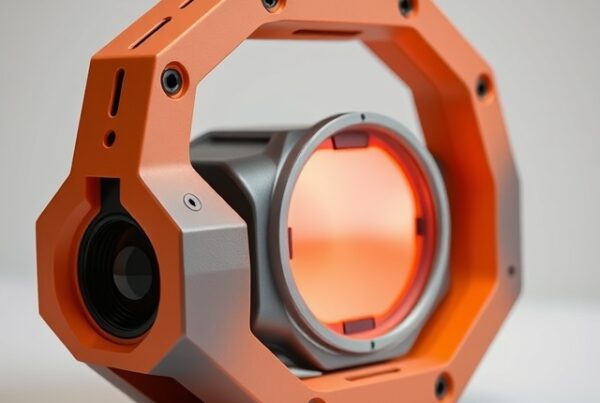

- 3D Printing: This rapid and versatile technique allows for the creation of complex 3D models directly from your digital design files.

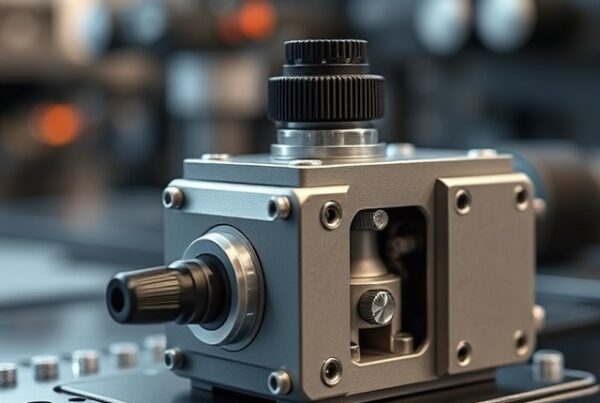

- CNC Machining: CNC machining is ideal for creating high-precision prototypes with intricate details and tight tolerances.

- Vacuum Forming: This cost-effective method is suitable for creating simple, low-volume prototypes out of plastic sheets.

Get a Prototype in Your Hands: Reach Out to Us to Discuss Your Prototyping Needs

We offer a variety of prototyping methods to suit your project requirements and budget. Whether you need a quick and functional model for user testing or a high-fidelity prototype to showcase to investors, we have the expertise and resources to make it happen.

Industrial Design Expertise at Design Catapult

Beyond prototyping, Design Catapult offers a complete suite of industrial design services. We can help you with:

- User-Centered Design: Our team prioritizes user experience at every stage of the design process.

- Design for Manufacturing (DFM): We ensure your product is designed for efficient and cost-effective production.

- Engineering Analysis: Our engineers utilize advanced tools to analyze your design and ensure its functionality and durability.

By collaborating with Design Catapult, you gain access to a team dedicated to turning your vision for a revolutionary airplane cart system into a reality.

Building Trust and Exceeding Expectations

Entrusting your vision to another company is a significant decision. At Design Catapult, we understand this and strive to build trust through open communication throughout the entire process. You’ll receive regular updates on the progress, have opportunities to provide feedback at every stage, and be involved in every key decision. Our commitment goes beyond simply meeting your expectations; we are passionate about exceeding them.

Ready to transform your innovative product from concept to reality? Contact Design Catapult today for a free consultation.

Learn More:

- Product Development Service

- Industrial Design

- Mechanical Engineering

- Prototyping

- Manufacturing Services

Industry Resources:

- The Society of Plastics Engineers (SPE): https://www.4spe.org/ (.org)

- The National Institute of Standards and Technology (NIST): https://www.nist.gov/ (.gov)